Case Study

Inventory for warehouse with barcode-based item tracking

Supply chain | Distribution | Inventory operations | Web + mobile

Client Overview

Green Planet is a large electronics distributor and authorized agency partner for multiple brands, managing product intake, storage, and dispatch across several warehouse locations.

Project Overview

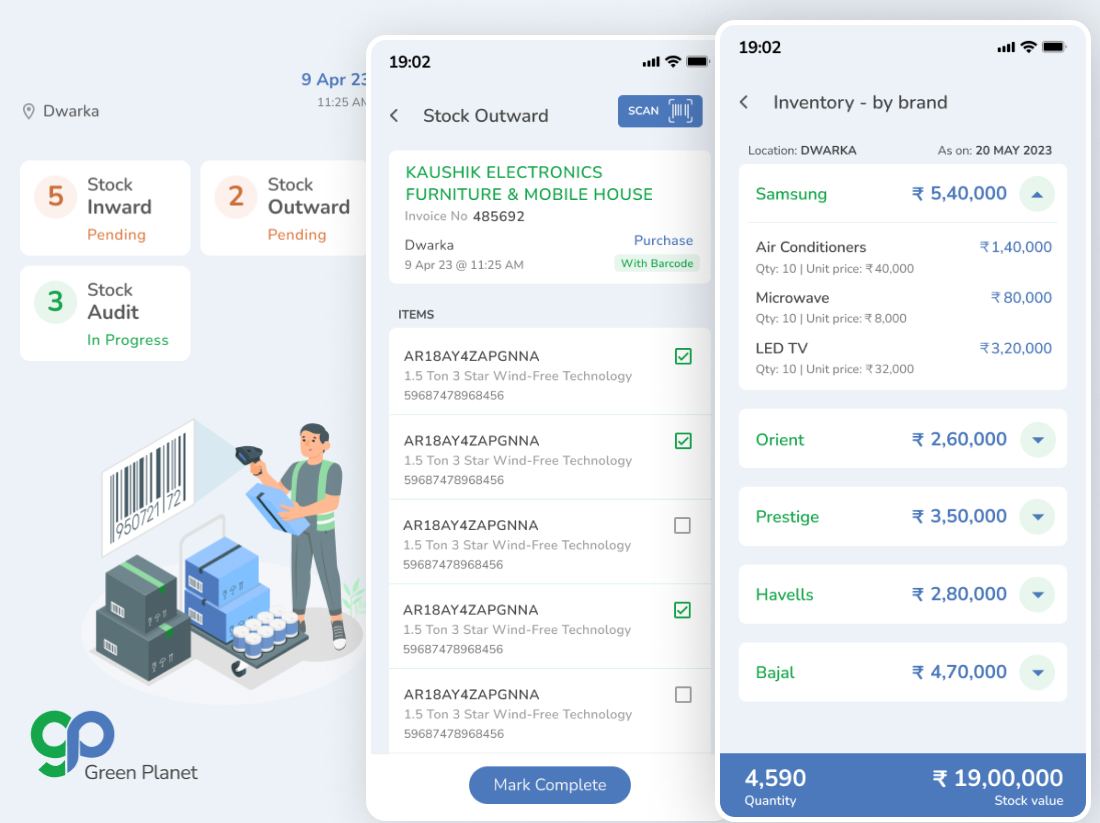

A web and mobile solution that digitizes warehouse workflows for stock receipt, dispatch, transfers, returns, and audits, using barcode-driven identification and tracking.

Business Challenge

Stock movement was recorded manually across multiple warehouses, making consistent item-level accountability difficult. Audits were time-consuming, and discrepancies were hard to trace. A centralized system was needed to enforce structured workflows, maintain accurate records, and provide real-time visibility across all operational activities.

Business Impact

Established item-level traceability across multiple warehouses

Reduced stock loss and misplacement through structured tracking

Improved accountability for warehouse operations and dispatch flows

Real-time visibility into stock value and movement for management

Solution Delivered

We designed and delivered an integrated web + mobile warehouse management system with barcode-based tracking, including support for TPP-244-Pro scanner workflows. The solution standardizes how stock is received, labeled, scanned, dispatched, audited, and reported across warehouse locations. Supervisors manage products, locations, and adjustments from the web application, while warehouse staff handle scanning and operations through the mobile app. Owners receive consolidated real-time dashboards that show product quantities, stock value, and movements across all warehouses.

Value Delivered

Tech Foundation

Angular

.NET Core

Flutter

TPP-244-Pro barcode Scanner Integration

Google Maps APIs