Use Cases of Machine Learning in Manufacturing

The Fourth Industrial Revolution, or Industry 4.0, an era of swift technological transformation, has seen the insertion of artificial intelligence into multiple industries. And manufacturing is one such major sector where automation is continuously upsurging, and machine learning (ML) is a crucial component of this digital transition.

Implementing Machine Learning can enable manufacturers to enhance industrial operations and OEE (operation equipment effectiveness) at any phase of the manufacturing process. In other words, tapping into the power of IOT (Internet of Things) can allow manufacturers to make decisions better and steer the business wheel forward. According to the Statista survey report, the global ML market size might grow remarkably in the years ahead.

This blog post intends to assist you in comprehending subjects such as how Machine Learning can enhance production operations for manufacturers, the advantages of Machine Learning, and its usage.

Let’s get started!

What is Machine Learning (ML)?

Machine learning is a branch of artificial intelligence that relies on neural networks and deep learning to teach itself, improving and adapting without programming when provided with a large quantity of data.

Now: let’s understand Machine Learning in Manufacturing Context

In the manufacturing industry, two machine learning models enhance the production process and related activities– supervised and unsupervised Machine Learning.

Supervised ML

Supervised ML utilizes Artificial Intelligence (AI) to extract patterns from extensive data sets with a predefined objective. Using it is advantageous in calculating the remaining useful life and predicting the likelihood of specific equipment malfunctioning.

Unsupervised ML

It concerns identifying patterns from data sets with unknown outcomes. For example, engineers and supervisors can utilize machine learning to detect strange anomalies and faulty elements in production.

Machine Learning solutions address data analytics, predictive maintenance, defect detection, quality control, product development and various other manufacturing-related applications.

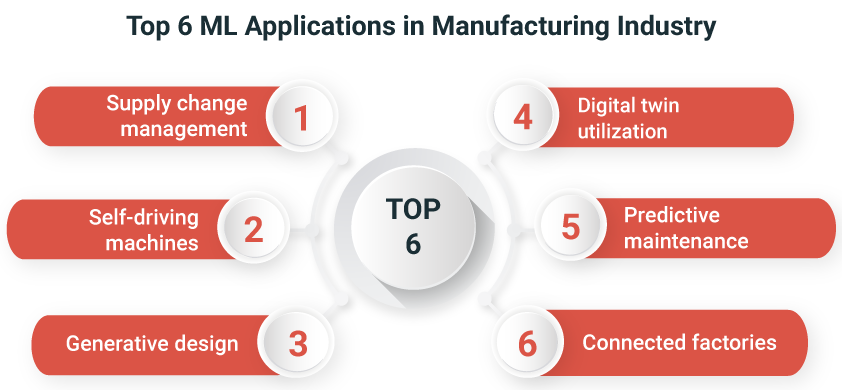

Top 6 ML Applications in the Manufacturing Industry

Look closely at the top six ML applications in the manufacturing industry to fully understand the tangled relationship between machine learning and manufacturing.

Insightful Supply Chain Management

With the spread of IIoT (Industrial Internet of Things) technology, intelligent supply chains might radically transform manufacturers’ operations. The first step on the ladder is automation, but entire supply chains may soon be “perceptive.” It implies they can automatically analyze statistics like inbound and outbound shipments, inventories, consumer preferences, market trends, etc. With the help of AI/ML techniques. Critical areas where perceptive supply chain management can be helpful are –

- Logistics route optimization

- Warehouse control

- Transport management

- Demand forecasting

ML for predictive maintenance

One of the main applications of machine learning in manufacturing is predictive maintenance, which uses algorithms to predict critical equipment or component failure. There are several ways ML technology can benefit manufacturers:

- Lower planned and unplanned downtime and optimizing expenses dramatically

- Enables technicians to focus on inspection, repair, and tool requirements

- Extend the Remaining Useful Life (RUL) of machinery by preventing secondary damage

- Minimizes the technical team size required for repairs.

Utilization of the Digital Twin

Manufacturers may perform rapid diagnostics, assess manufacturing processes, and forecast performance using a digital twin—a real-time virtual version of a physical thing or process. Further, digital twins can enable complete design, production, and operational customization, which can help firms modernize their engineering practices. The perks of ML-enabled digital twins in the manufacturing sector include the following:

- Significant cost reductions

- Enhancing production line reliability

- Full customization and improved quality

- Rationalized maintenance

- Optimized performance and productivity

Generative design

AI and ML can build almost any design solution to match any problem/product, depending on pre-established components such as size, weight, materials, etc. It allows engineers to find an excellent design solution for a product before going into production. ML (machine learning) applies generator and discriminator models to –

- Building new product designs for specialized products

- Identify between the authentic and generated products

- Instructing deep learning algorithms to recognize and define all potential design solutions to optimize the design for a given goal.

Self-driving machines

As per the McKinsey report, self-driving vehicles might contribute 10-15% to global car sales in 2030, with a two-digit annual growth rate by 2040. With AI, these cars can be efficient, reliable, and integrated with data processing. Execution of ML technology can help manufacturers –

- Automate everything from assembly lines to conveyor belts

- Quicken time-to-market

- Detection of road objects, interpretation of road signs & situations, and identification of crossroads contribute to road safety.

Machine Learning for Connected Factories

Embracing Industry 4.0 is the way forward for the manufacturing industry. The world of smart manufacturing will soon replace and disrupt the space giving birth to smart factories. It implies digitizing operations and empowering them with networked capabilities to enable seamless data exchange. The plus points of ML for smart manufacturing are –

- Allows seamless transfer of data and insights between people, machines, and sensors

- Reduces customer shake and improves efficiency across procedures

- Offers a thoughtful way of managing logistics, analyzing compliance risk, and inventory

Advantages of ML Technology for Manufacturers

A reliable technology partner can assist you in fully capitalizing on the enormous potential benefits of ML technology within the industry. Listed below are some of the most notable advantages that ML technology offers for the manufacturers –

- Significant loss reductions due to processes

- Process optimization enhances capability

- Predictive maintenance can help save costs

- Predictive analytics boost inventory management

- Makes supply chain management more efficient

- Increases quality control

Leverage Machine Learning’s (ML/AI) True potential with Mind IT®

Manufacturers can take their business to the next level by leveraging the enormous potential of ML and other 4IR technologies, such as AI, IoT, and big data analytics. They can reap tremendous benefits from implementing machine learning, including a reduction of 10%-20% in quality-related costs and a 15%-30% increase in labour productivity.

At Mind IT®, we legitimize our clients to restructure their business scenes and develop highly integrated ecosystems with the help of our advisory and consulting practices. Our objective is to enhance the effectiveness of business operations and bolster companies worldwide through investments in technology.

Share this post

About the Author

Sujoy Roy

(Head – Digital Marketing)

From my teenage time, I had a quench to solve problems and loved leadership. Starting my career in relation management, ignited my passion for managing people. While managing I realized technology needs to be incorporated to keep pace with the changing world & do my work efficiently.